| Quantity: | |

|---|---|

JHK-P12 Front Door Designs Hotel Room PVC Door

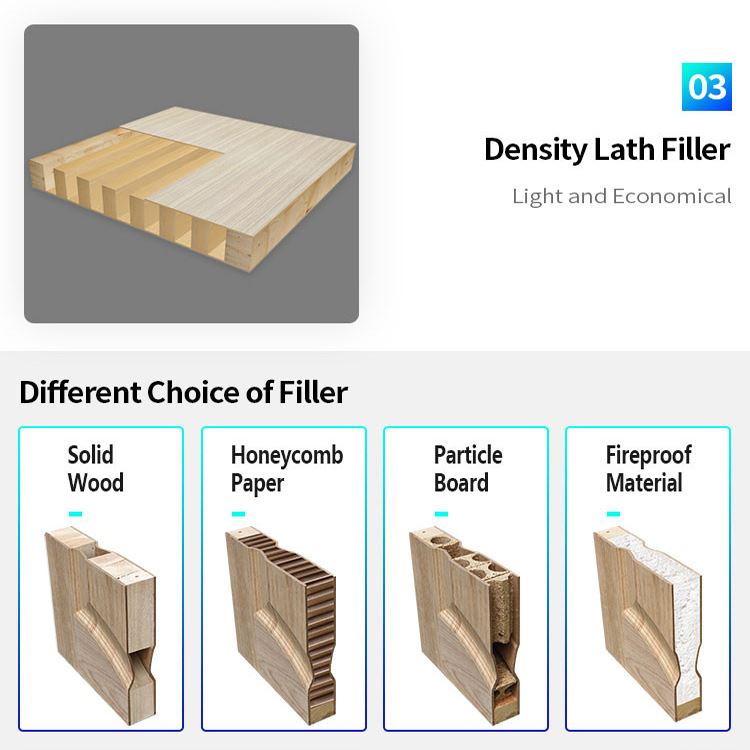

The molded door panel is the main material for the production of molded door.

Mold presses a door to produce a craft to be simple, the pattern is fixed, suit to standardize batch processing, because its main material recombines via fiber and become whole board structure, get rid of the problem that natural lumber internal stress is uneven, not easy craze, not easy deformation.

In order to ensure that the molded doors have the effect of wood doors and solid wood composite doors, there are also fiberboard with PVC leather veneer.

Existing on the surface of the PVC leather upholstery fiberboard, were flat facing or by carving milling model, the method of this structure in the actual production surface stereo is not strong, the milling type of panel required thickness more than 4 mm, the thickness of thin, milling the corresponding concave and convex chamfer, and the depth of the type and the surface milling cannot too deep, poor overall stereo feeling, milling of fiber dust pollution environment, the production cost is very high.

Additional, with face plate too thick, cannot achieve concave and convex stereo feeling effect, very wasteful lumber resource again.

FAQ:

1. When did your company establish?

JHK: Since 2000, we are a manufacturer with 15 years’ experience.

2. How many people work in your company?

JHK: About 500 People.

3. What is the capacity of production per year?

JHK: More than 500,000 PCS.

4. What raw materials of wood do you have?

JHK: Natural wood and EV wood are both available. Red oak, ash, teak and mahogany are our recommended materials.

5. What is the MOQ?

JHK: One 20’ container, which can hold 2500-3000 PCS door skins. Sample order is also available.

6. What is the delivery time?

JHK: It will be around 40 days after receiving the payment.

7. Can I visit your factory?

Yes, of course! We are very welcome for your visiting, and we will pick you up at the YIWU airport or the Jinhua railway station.

8. How about your after-sale service?

JHK: We guarantee our customers one-year warranty, and will deliver forever service no matter before or after the sale.

JHK-P12 Front Door Designs Hotel Room PVC Door

The molded door panel is the main material for the production of molded door.

Mold presses a door to produce a craft to be simple, the pattern is fixed, suit to standardize batch processing, because its main material recombines via fiber and become whole board structure, get rid of the problem that natural lumber internal stress is uneven, not easy craze, not easy deformation.

In order to ensure that the molded doors have the effect of wood doors and solid wood composite doors, there are also fiberboard with PVC leather veneer.

Existing on the surface of the PVC leather upholstery fiberboard, were flat facing or by carving milling model, the method of this structure in the actual production surface stereo is not strong, the milling type of panel required thickness more than 4 mm, the thickness of thin, milling the corresponding concave and convex chamfer, and the depth of the type and the surface milling cannot too deep, poor overall stereo feeling, milling of fiber dust pollution environment, the production cost is very high.

Additional, with face plate too thick, cannot achieve concave and convex stereo feeling effect, very wasteful lumber resource again.

FAQ:

1. When did your company establish?

JHK: Since 2000, we are a manufacturer with 15 years’ experience.

2. How many people work in your company?

JHK: About 500 People.

3. What is the capacity of production per year?

JHK: More than 500,000 PCS.

4. What raw materials of wood do you have?

JHK: Natural wood and EV wood are both available. Red oak, ash, teak and mahogany are our recommended materials.

5. What is the MOQ?

JHK: One 20’ container, which can hold 2500-3000 PCS door skins. Sample order is also available.

6. What is the delivery time?

JHK: It will be around 40 days after receiving the payment.

7. Can I visit your factory?

Yes, of course! We are very welcome for your visiting, and we will pick you up at the YIWU airport or the Jinhua railway station.

8. How about your after-sale service?

JHK: We guarantee our customers one-year warranty, and will deliver forever service no matter before or after the sale.