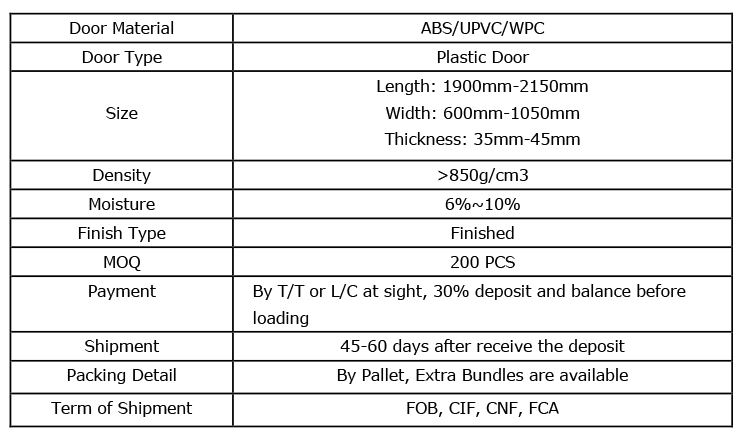

| Quantity: | |

|---|---|

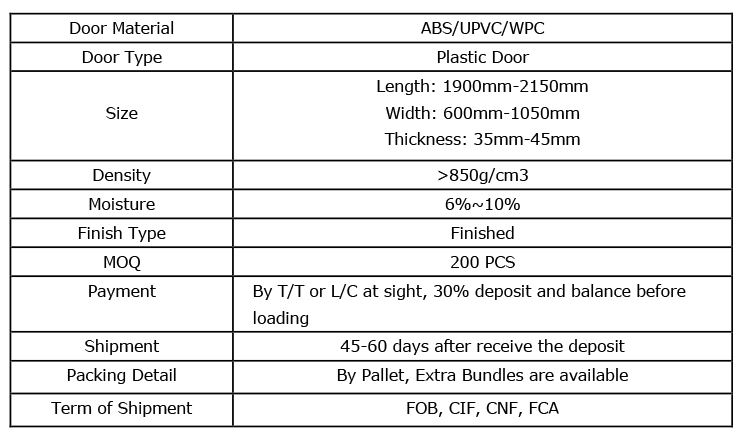

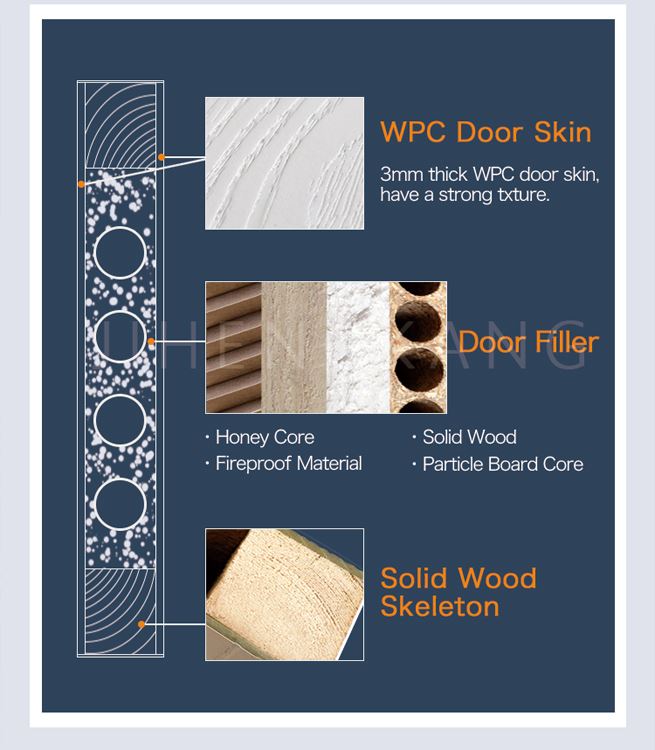

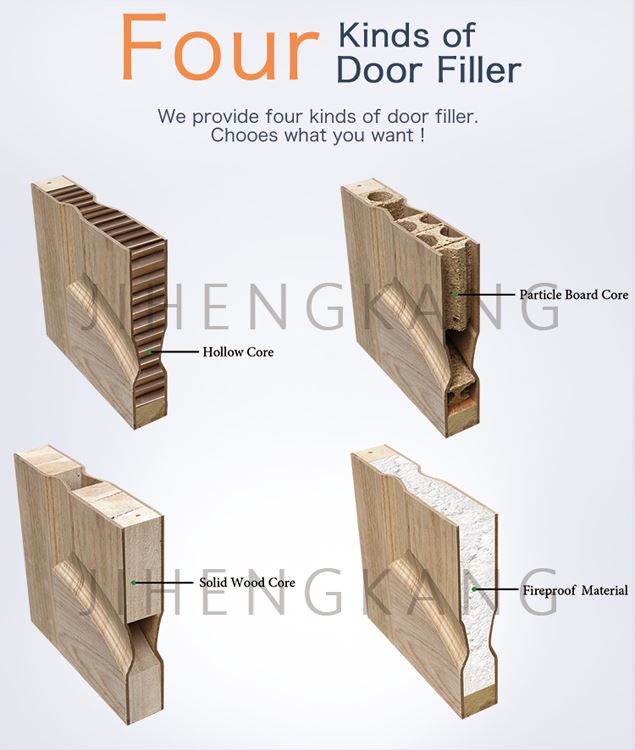

WPC DOOR Advantages

100% Eco-friendly product

Solid door structure with absolute strength

Best to stand with high moisture and humidity level

High tensile strength

High screw holding capacity

Better maintainability

Can be processed like natural wood, MDF, Plywood on any panel processing machine

Corrosion resistance

Nontoxic and borer free

Easy to cut and saves tooling life almost 30 % than MDF and particle boards

Anti-abrasiveness

High temperature resistance

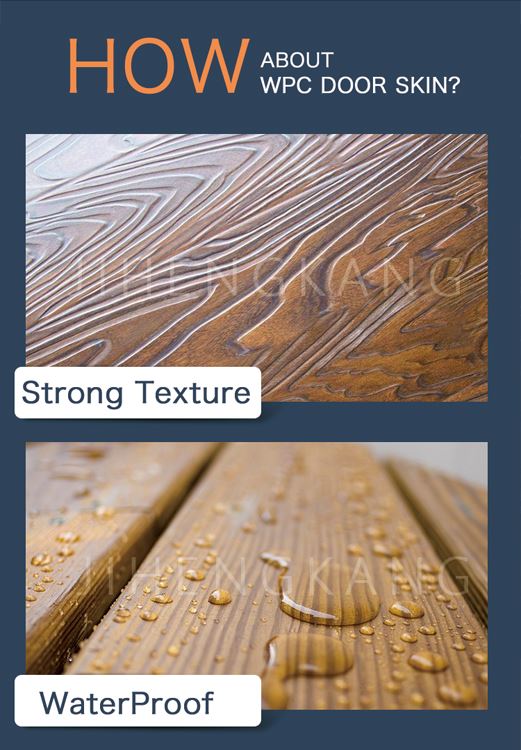

Perfect surface finishing

Accuracy in dimensions

Maintenance free

No Paint & No Polish required

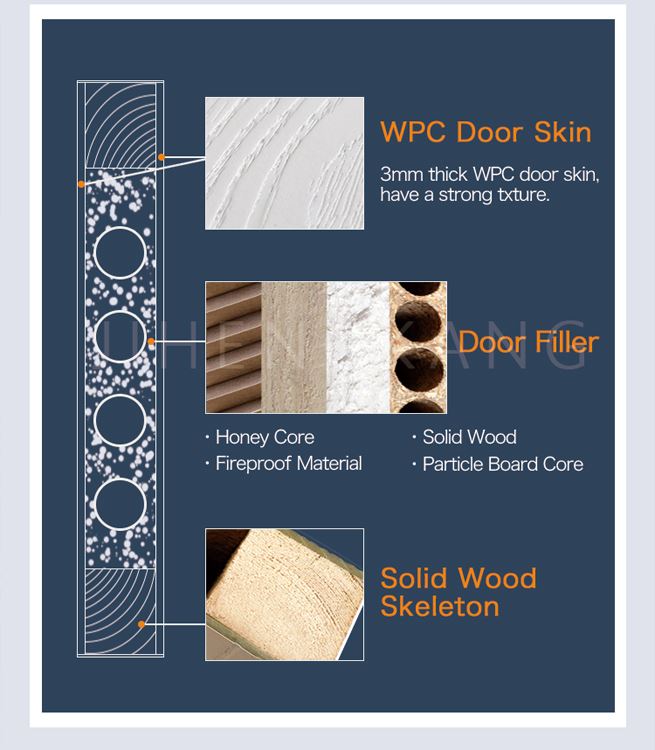

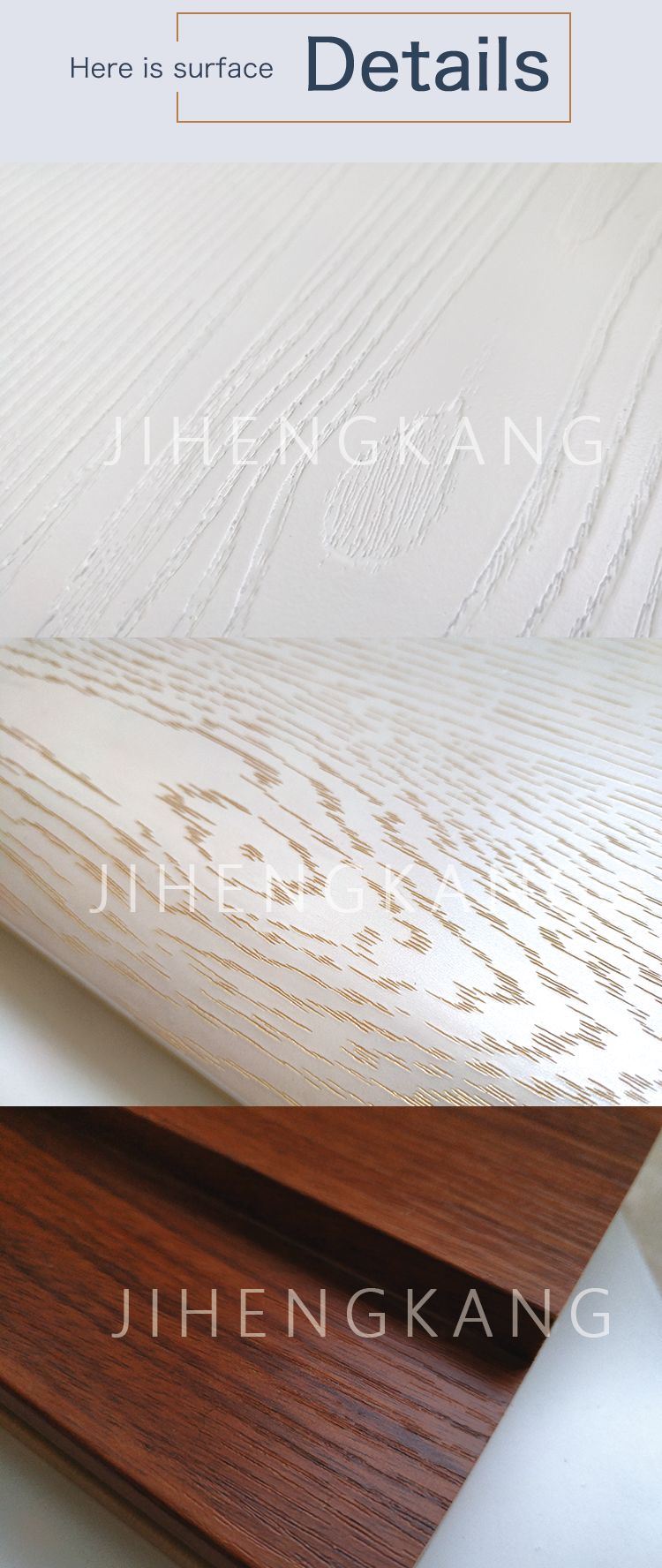

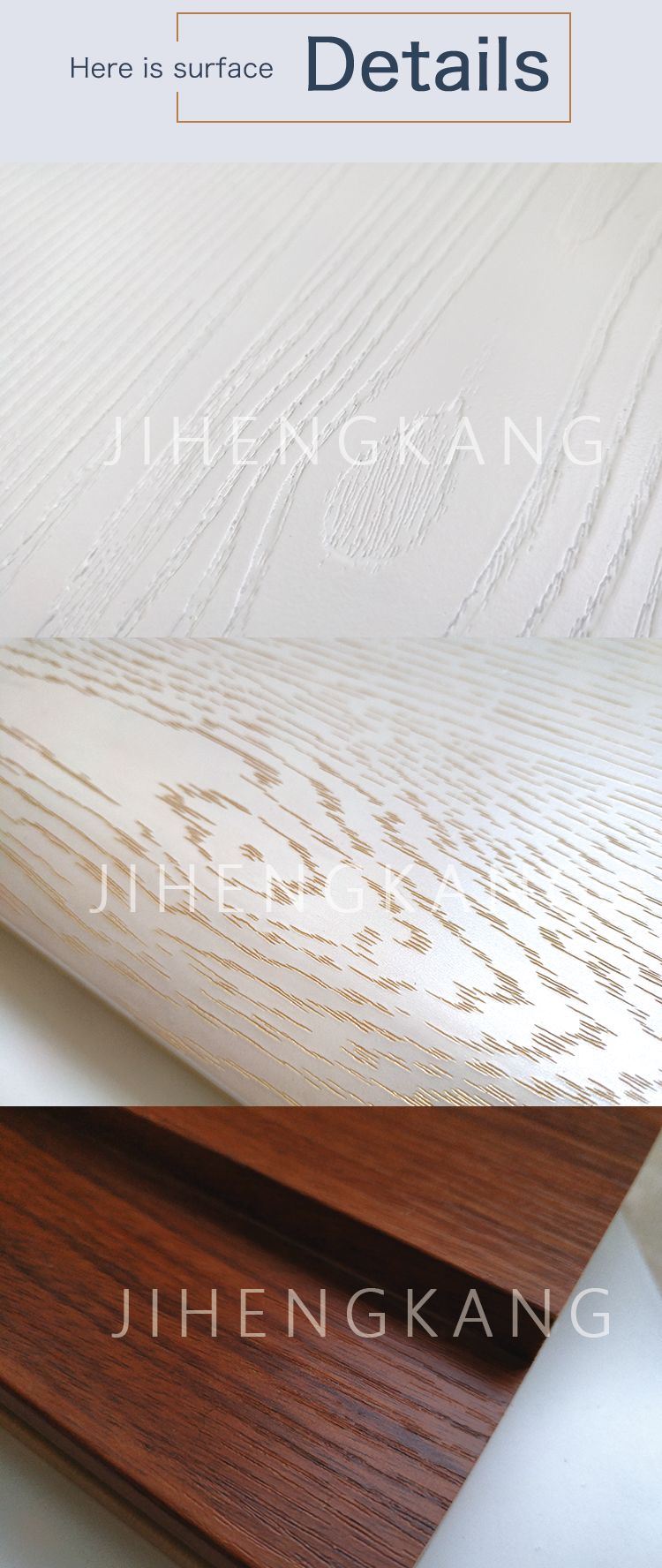

Surface decoration of WPC DOOR

Can treated with HPL lamination

Best routed with CNC router

Can be applied with PVC foil lamination on Vacuum press

PVC edge bending can be applied nicely

Paper lamination can be done easily

PU coating and UV coating can be done

Printing can be done with high resolution

Surface can be painted

Foil transfer mechanism

Moldings can be applied

Light weight structure

FAQ:

1. When did your company establish?

JHK: Since 2000, we are a manufacturer with 15 years’ experience.

2. How many people work in your company?

JHK: About 500 People.

3. What is the capacity of production per year?

JHK: More than 500,000 PCS.

4. What raw materials of wood do you have?

JHK: Natural wood and EV wood are both available. Red oak, ash, teak and mahogany are our recommended materials.

5. What is the MOQ?

JHK: One 20’ container, which can hold 2500-3000 PCS door skins. Sample order is also available.

6. What is the delivery time?

JHK: It will be around 40 days after receiving the payment.

7. Can I visit your factory?

Yes, of course! We are very welcome for your visiting, and we will pick you up at the YIWU airport or the Jinhua railway station.

8. How about your after-sale service?

JHK: We guarantee our customers one-year warranty, and will deliver forever service no matter before or after the sale.

WPC DOOR Advantages

100% Eco-friendly product

Solid door structure with absolute strength

Best to stand with high moisture and humidity level

High tensile strength

High screw holding capacity

Better maintainability

Can be processed like natural wood, MDF, Plywood on any panel processing machine

Corrosion resistance

Nontoxic and borer free

Easy to cut and saves tooling life almost 30 % than MDF and particle boards

Anti-abrasiveness

High temperature resistance

Perfect surface finishing

Accuracy in dimensions

Maintenance free

No Paint & No Polish required

Surface decoration of WPC DOOR

Can treated with HPL lamination

Best routed with CNC router

Can be applied with PVC foil lamination on Vacuum press

PVC edge bending can be applied nicely

Paper lamination can be done easily

PU coating and UV coating can be done

Printing can be done with high resolution

Surface can be painted

Foil transfer mechanism

Moldings can be applied

Light weight structure

FAQ:

1. When did your company establish?

JHK: Since 2000, we are a manufacturer with 15 years’ experience.

2. How many people work in your company?

JHK: About 500 People.

3. What is the capacity of production per year?

JHK: More than 500,000 PCS.

4. What raw materials of wood do you have?

JHK: Natural wood and EV wood are both available. Red oak, ash, teak and mahogany are our recommended materials.

5. What is the MOQ?

JHK: One 20’ container, which can hold 2500-3000 PCS door skins. Sample order is also available.

6. What is the delivery time?

JHK: It will be around 40 days after receiving the payment.

7. Can I visit your factory?

Yes, of course! We are very welcome for your visiting, and we will pick you up at the YIWU airport or the Jinhua railway station.

8. How about your after-sale service?

JHK: We guarantee our customers one-year warranty, and will deliver forever service no matter before or after the sale.